Tuesday, July 10, 2012

Ice Dyeing

I'm a little late on the ice dyeing craze, and this may seem like a strange time to do it, but I finally made time to try it. I read about snow dyeing several years ago and thought it sounded interesting, although not very practical for someone who lives in a warm climate. Ice dyeing makes more sense, and summer is actually a good time, because the mess can stay outside.

The nudge to do this came when I was invited to participate in a friend's booth at the American Sewing Guild conference in August. She invited me to sell my books and DVDs and said that fat quarters would be great, too. Ice dyeing seemed the perfect way to create unique fabric for fat quarter sets.

After doing an internet search, I realize there are many variations. I chose to work with the dyes in their powdered state rather than mixing them into a liquid. I placed a tarp on the ground outside and used a plastic grid from a commercial light fixture to raise the fabric out of the melting ice/dye. I didn't document the process, but I'm doing more later this week, so I'll take photos of my setup. At that time I'll also give more detail about the process I used.

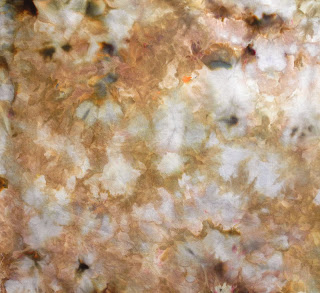

I am pleased with the results, although I have to admit that while it was in process I was not impressed. I had read some comments that the results are similar to what you get with low water immersion dyeing. I found a significant difference. The patterning is hard to describe, but it has a distinctive look. Here are my results (I used Dharma Bronze and ProChem Tobacco on all these pieces):

This is a full and detail shot of a piece of silk dobby noil (from Thai Silks). It is a wonderful fabric and it took the ice dyeing beautifully.

This is a heavy-weight cotton. See how much difference in how the colors took?

This is silk habotai, and it was underneath the two previous fabrics to catch the dye as it dripped down. This looks like a typical low water immersion dye.

This is also cotton, and it was dry when I placed the ice cubes on top. The other fabrics were all wet.

This piece was underneath the plastic grid to catch the drips from the previous cloth.

Have you tried ice and snow dyeing? What was your experience?

Labels:

ice dyeing,

surface design techniques

Subscribe to:

Post Comments (Atom)

My dying experience ended up with faded colors. They ran out in the rinse. I presoaked with soda ash. I waited 24 hours before rinse. I used tshirts from Walmart,Danskin cotton,white. Any suggestions,your outcome was awesome. Oh I also used Cushings dyes.

ReplyDeleteHi Pearl,

ReplyDeleteThe dye is the critical issue here. Cushing's dyes are a direct dye and require heat - 175-200 degrees. They are usually used for immersion on the stove top. I used Procion-type fiber reactive dyes. Fiber reactive dyes require a much lower temperature. A good example of how the materials used impact the end results!

Thank you so much...I'm gonna order some Procion and give it another try. I love the browns that you used. After you dyed did you use anything in the rinses? I am new to dying so I guess you have to have some flubs. I have done alpaca and wool dying natural and synthethic. So that has got me interested so much.

ReplyDeleteYou should have much better results with the Procion! No, I didn't use anything in the rinse. I found that there was very little dye run off in the rinsing. I rinsed in cold water, then washed them in the washing machine on hot - no detergent.

ReplyDeleteGood luck!

thanks for all your help...will let you know my next results.

ReplyDelete